Saf-T-Anchors

Patent Pending

No single anchor is perfect for every situation, as soil classifications can vary greatly even within a

small area. Oklahoma Design Technologies aims to provide the ideal anchor for each unique

scenario by offering a diverse range of anchors and installation methods.

Saf-T-Anchors are not galvanized because galvanized anchors can be damaged during installation,

exposing the metal to circulating currents that cause deterioration within approximately 5 to 7

years. In contrast, Saf-T-Anchors are made from Cor-Ten material with nickel, designed to rust just

enough to insulate the metal without succumbing to circulating currents, thus outlasting any other

anchor on the market.

Saf-T-Anchors with 3/4" rods are installed left-handed, using a battery-operated impact tool, which

has four times more torque for removal than installation. Saf-T-Anchors with 1" rods are installed

using ODT's Kelly Bar Adaptor. The anchors' graduated flights, smaller at the bottom and larger

towards the top, allow the anchor to pull itself into the soil like a screw. This design means the

boom operator doesn't need to push the anchor in, preventing the creation of a void and resulting

in increased holding strength due to the compact soil above the anchor and the creation of a

compressed ball pushing out into the walls of the disturbed soil.

The Saf-T-Achor excels in four key areas:

1. Ease of Installation - Requires less torque, reducing strain on personnel and equipment, and shortens installation time. A single employee can replace compromised anchors efficiently, saving both time and money.

2. Superior Holding Strength - Made from Cor-Ten material, which possesses double the breaking strength of other metals. The permanent Saf-T-Anchors feature a compactor beneath the flights that compresses soil while being screwed into the ground, creating a compacted soil ball for instant holding power at reduced depths.

3. Longevity - Cor-Ten material resists deterioration from circulating currents, lasting significantly longer and cutting overhead costs by eliminating the need to replace anchors every 5 to 7 years.

4. Cost Savings - When comparing the total cost of installing helix anchors versus Saf-T-Anchors, the latter is less expensive to install, has a longer lifespan, and is safer for personnel.

With the progression towards electric vehicles, the increase in underground circulating currents will accelerate the degradation of galvanized anchors, potentially compromising the electrical grid.

Explore the diverse range of anchoring solutions offered by Oklahoma Design Technologies.

Impact Installed Anchors

The Saf-T-Anchors with the 3/4" rod are installed with a battery-operated impact or with the T-Handle with a ratchet & socket.

Click the picture

Truck Installed Anchors

The Saf-T-Anchors with the 1" rod are installed with a truck or skid steer using ODT's Kelly Bar Adaptor.

Click the picture

Swamp Anchors

The Swamp anchor is designed specifically to penetrate the sub-soil which is on average 70 inches below the surface in swampy, sandy or mucky areas where unstable soil is present.

Click the picture

Anchor Rod Extensions

The Saf-T-Anchors can be installed to a greater depth by using the Saf-T-Anchor Rod Extension when soil conditions are not ideal to provide the required holding strength.

Click the picture

Temporary Anchors

The distinction between a permanent anchor and a temporary anchor lies in the presence of a compactor beneath the flites. A temporary anchor lacks this compactor, which facilitates its easier installation and removal on multiple occasions.

Click the picture

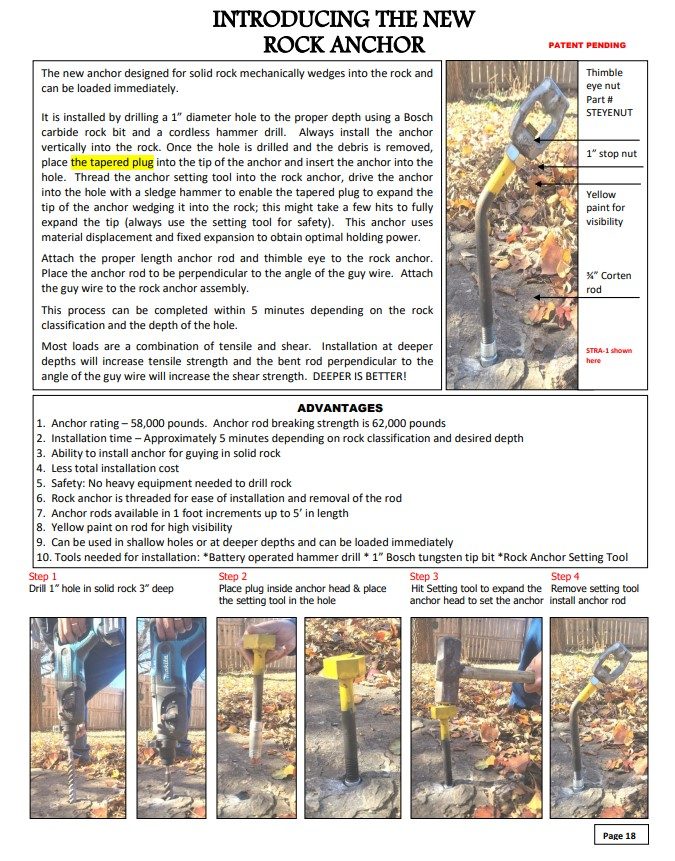

Rock Anchors

The Rock Anchor is engineered for solid rock, where it mechanically wedges and can be subjected to load immediately.

Click the picture

Distribution Wing Anchor

The Distribution Wing Anchor boasts significant holding power as its wings are driven into undisturbed soil. This penetration into untouched soil results in immediate holding strength and completely prevents anchor creep.

Transmission Wing Anchor

The diameter of the Transmission Wing Anchor plate is 17 inches, which extends to 21 inches when the wings are fully deployed. The nine wings penetrate undisturbed soil, effectively preventing anchor creep.

Click the picture

Click the picture

Anchor Comparison

See the difference between the Saf-T-Anchor and a helix anchor

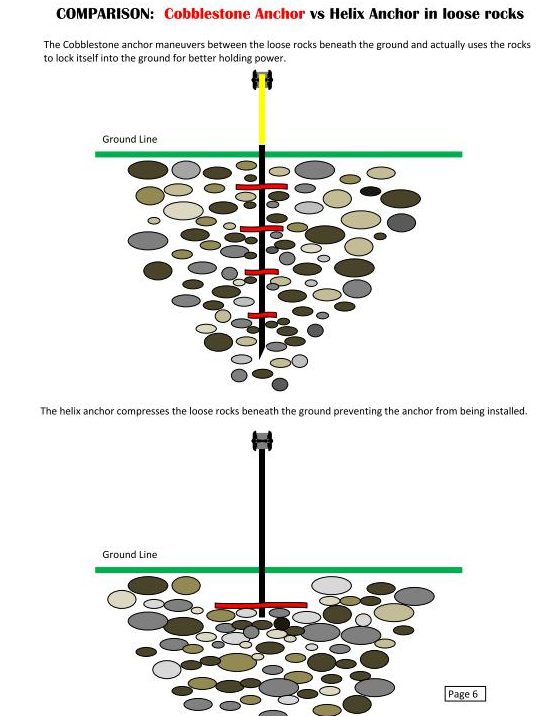

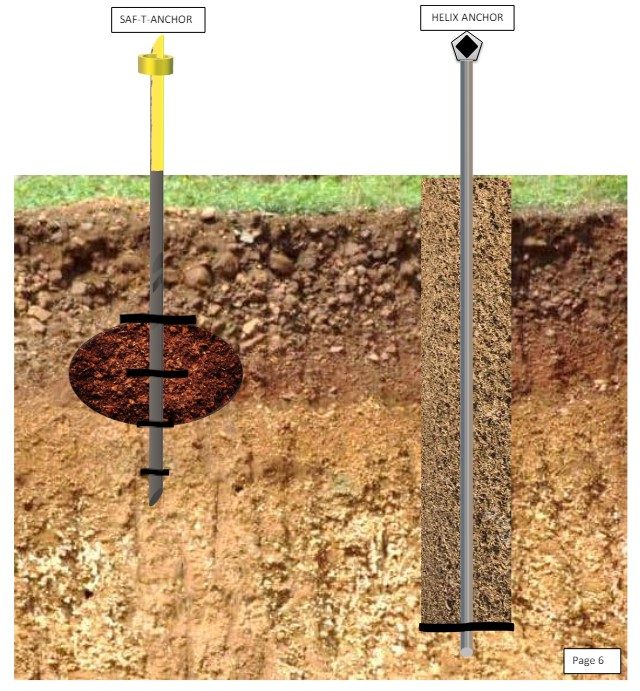

The graduated flight sizes on the Saf-T-Anchor slice through the soil, leaving it undisturbed. Compactors push the soil downward while the anchor is screwed into the ground, creating a ball of compressed soil that expands outward, compacting the surrounding soil. This process provides the Saf-T-Anchor with instant holding strength.

In contrast, the larger single flight on the helix anchor is pushed down, creating a column of loose dirt atop the flight. The absence of compressed dirt to secure the anchor in the ground means that the helix anchor may continue to shift and could be pulled out of the ground when tension is applied.

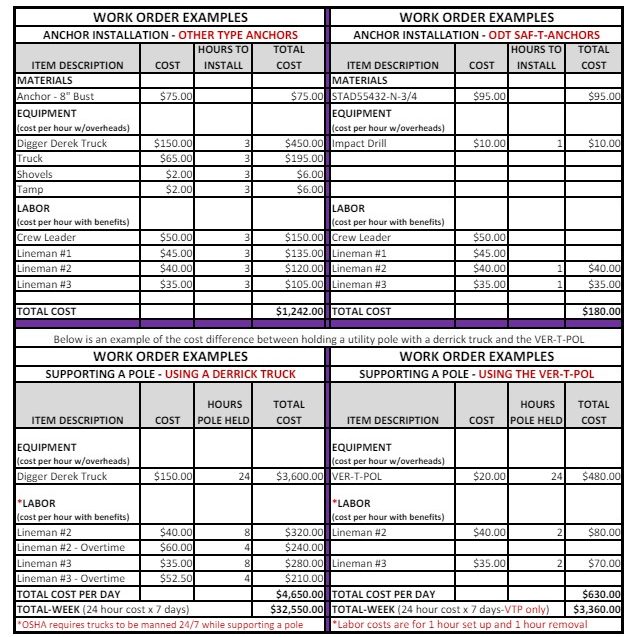

Work Order Cost Example

In comparing the costs of installing an anchor, it's essential to consider all overhead expenses.

Providing a work order example can give the buyer an estimated total cost per installation.

While the figures in the example are hypothetical, they can be assembled using industry-standard daily rental rates or your company's actual costs, inclusive of all overheads and employee benefits.

Click on the image above to view the full size

©Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.