Ver-T-Pol

Patented Product

Ver-T-Pol

Patented Product

The VER-T-POL, a patented product, is certified by a Professional Engineer to support a working load of 21 tons (42,000 pounds).

Installing the VER-T-POL at your job site is considered acting in the best interest of your employees' safety, while also enhancing productivity and saving money for your company.

The VER-T-POL stands as the world's sole portable mechanical aluminum device that has professional certification to support up to 21 tons in a vertical position for an extended duration.

A significant advantage is the capability to install or remove VER-T-POL portable supports in areas where line or boom trucks cannot reach, known as blind easement situations. Installation requires one to two men and takes about 15 minutes, with removal taking approximately 10 minutes.

For the safety of both the public and the company, VER-T-POL portable structure supports are recommended as a standard safety tool. These supports are versatile, cost-effective, easy to install, and reusable, making them a favorite among utility, municipal, and construction companies.

In essence, the VER-T-POL delivers on three critical aspects: safety, cost savings, and customer reliability. The system not only meets but also exceeds ANSI & OSHA standards and comes with a Professional Engineer's certification.

Pictures of the Ver-T-Pol

Videos of the Ver-T-Pol

Ver-T-Pol - POLE SUPPORT SPECS:

- Constructed out of high tensile aluminum and steel.

- Designed to support 42,000 vertical pounds.

- Constructed using pins/rods to be quickly assembled and disassembled in the field.

- Designed to be maintenance free and to be easily upgraded.

- Chains are 5/16”, high-grade (70,000 lbs.), steel construction.

- Hooks are high-grade (70,000 lbs.) steel construction.

- Recommended installation of anchor is 1’ behind center base plate, no further than 4’.

- Top support chain attached to pole, roughly 6' to 7’ from ground level.

- Bottom tension chain to be attached roughly 2’ above ground level.

- Chains and 2” nylon straps to be used when excavation near or around pole.

- One wrap of nylon strap will hold 2,000 lbs.; two raps will hold 4,000 lbs.

- Three 2” straps are required.

- The heaviest piece weighs 70 lbs. The complete unit weighs 550 lbs.

COST SAVING PURPOSES:

- Not having to relocate pole, due to excavation and trenching near pole.

- Overtime, not having to replace broken or rotted pole on overtime.

- Safety, not knowing if pole is safe to climb, due to pole rotted off below ground line.

- Allowing Engineer to concentrate on more productive jobs, instead of designing line to be relocated and moved back to original location after construction of underground facilities.

- To keep damage claims to a minimum.

- Help keep SAIDI and CAIDI values to a minimum.

- After damaging storms, installing pole supports allows construction crews to do more productive work by concentrating on higher customer outage areas.

- To help minimize liabilities and law suit related to extended exposure of using a line truck to hold pole.

USAGE:

- For supporting a pole, when construction or maintenance of underground facilities are near or under pole.

- For stabilizing a broken pole.

- For helping set a pole when no motorized vehicle can set a pole.

- For holding a deadend pole when downguys have to be temporarily removed.

- Can be used in downtown underground network, to help train/guide underground cables into manholes.

- Can be used to support bridge columns, traffic signal poles, walls, beams or anything vertical.

TESTING:

- Pole supports have been field tested since 2001.

- There have not been any personal injuries recorded.

- No liability or damage claims have been filed toward the pole support.

- Some examples of poles held by the VER T POL pole support:

- 25’ distribution through 80’ transmission poles

- Tangent 50’ pole with 3-167kVA transformers and 3-phase 477ACSR conductors.

- Running 45’ angle pole with 1-75kVA transformer, with downguys removed.

- Numerous junction poles with large telephone and cablevision trunk cables.

PAGE 107 & 108 – WWW.OSHA.GOV – LEAVING EQUIPMENT UNATTENDED

OSHA is making this document, the regulatory text, available for informational purposes only. This action does not affect the effective date of the final rule on Cranes and Derrick in Construction, which will be 90 days after August 9, 2010, the date the final rule will be published in the Federal Register. Until the date of publication, this full rule, including the preamble, can be found at http://www.ofr.gov/inspection.asps. After publication the rule can be found at the Federal Register at www.osha.gov.

(1) Where the manufacturer procedures are unavailable, the employer must develop and ensure compliance with all procedures necessary for the safe operation of the equipment and attachments.

(2) Procedures for the operational controls must be developed by a qualified person.

(3) Procedures related to the capacity of the equipment must be developed and signed by a registered professional engineer familiar with the equipment.

(c) Accessibility of procedures.

(1) The procedures applicable to the operation of the equipment, including rated capacities (load charts), recommended operating speeds, special hazard warnings, instructions, and operator’s manual, must be readily available in the cab at all times for use by the operator.

(2) Where rated capacities are available in the cab only in electronic form; in the event of a failure which makes the rated capacities inaccessible, the operator must immediately cease operations or follow safe shut-down procedures until the rated capacities (in electronic or other form) are available.

(d) The operator must not engage in any practice or activity that diverts his/her attention while actually engaged in operating the equipment, such as the use of cellular phones (other than when used for signal communications).

(e) Leaving the equipment unattended.

(1) The operator must not leave the controls while the load is suspended, except where all of the following are met:

(i) The operator remains adjacent to the equipment and is not engaged in any other duties.

(ii) The load is to be held suspended for a period of time exceeding normal lifting operations.

(iii) The competent person determines that it is safe to do so and implements measures necessary to restrain the boom hoist and telescoping, load, swing, and outrigger or stabilizer functions.

(iv) Barricades or caution lines, and notices, are erected to prevent all employees from entering the fall zone. No employees, including those listed in §§ 1926.1425(b)(1) through (3), § 1926.1425(d) or § 1926.1425(e), are permitted in the fall zone.

(2) The provisions in § 1926.1417(e)(1) do not apply to working gear (such as slings, spreader bars, ladders, and welding machines) where the weight of the working gear is negligible relative to the lifting capacity of the equipment as positioned, and the working gear is suspended over an area other than an entrance or exit.

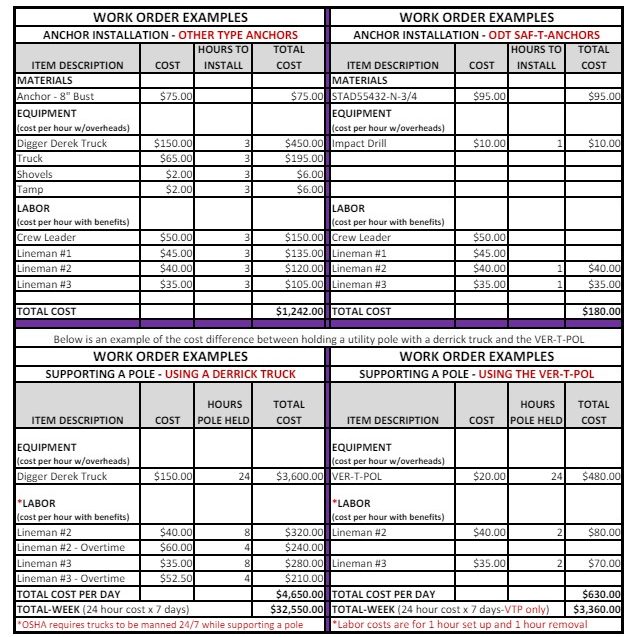

Work Order Cost Example

In comparing the costs of supporting a utility pole with a line truck versus using the Ver-T-Pol, it's essential to consider all overhead expenses.

Providing a work order example can give the buyer an estimated total cost per day.

While the figures in the example are hypothetical, they can be assembled using industry-standard daily rental rates or your company's actual costs, inclusive of all overheads and employee benefits.

©Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.