Process & Procedures

Using Oklahoma Design Technologies' Innovative Products

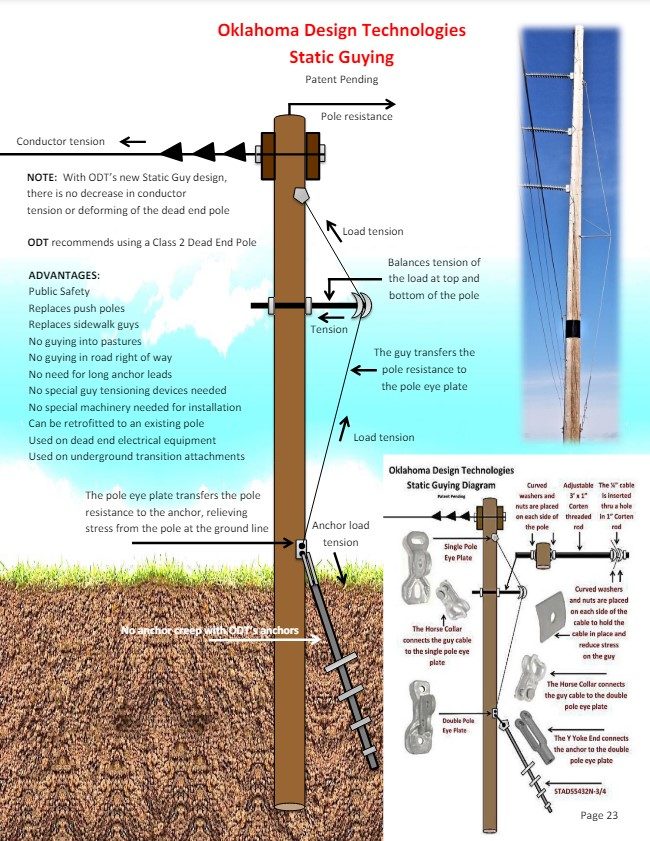

Static Guying

The key to the success of this procedure is the use of the Saf-T-Anchor

ADVANTAGES:

Public Safety, Replaces push poles, Replaces sidewalk guys, No guying into pastures, No guyhing in road right of way, No need for long anchor leads, No special guy tensioning devices needed, No special machinery needed for installation, Can be retrofitted to an existing pole, Used on dead end electrical equipment, Used on underground transition attachments.

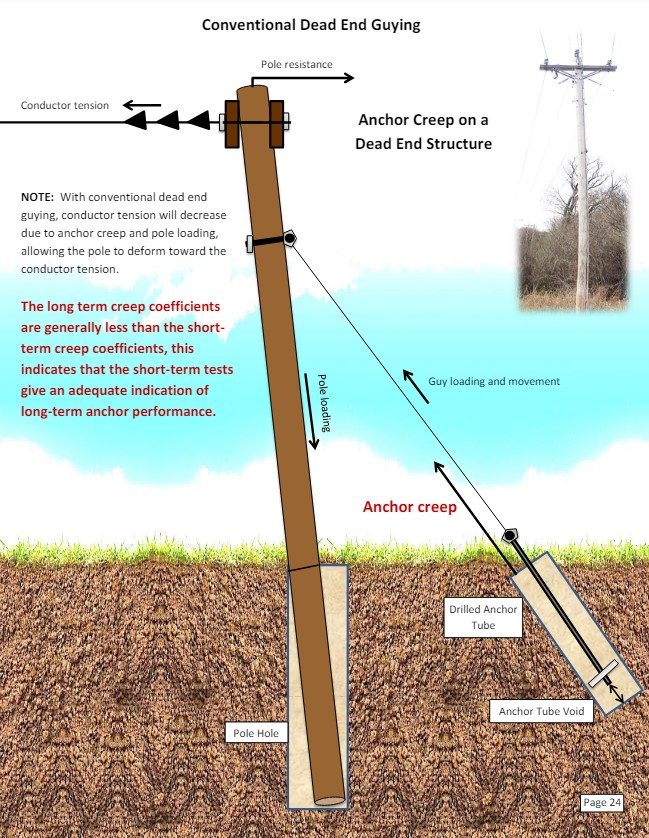

Conventional Dead-End Guying

The key to the success of this procedure is the use of the Saf-T-Anchor

With conventional dead-end guying, conductor tension will decrease due to anchor creep and pole loading, allowing the pole to deform toward the conductor tension.

Pole Anti-Jack Assembly

The key to the success of this procedure is the use of the Saf-T-Anchor

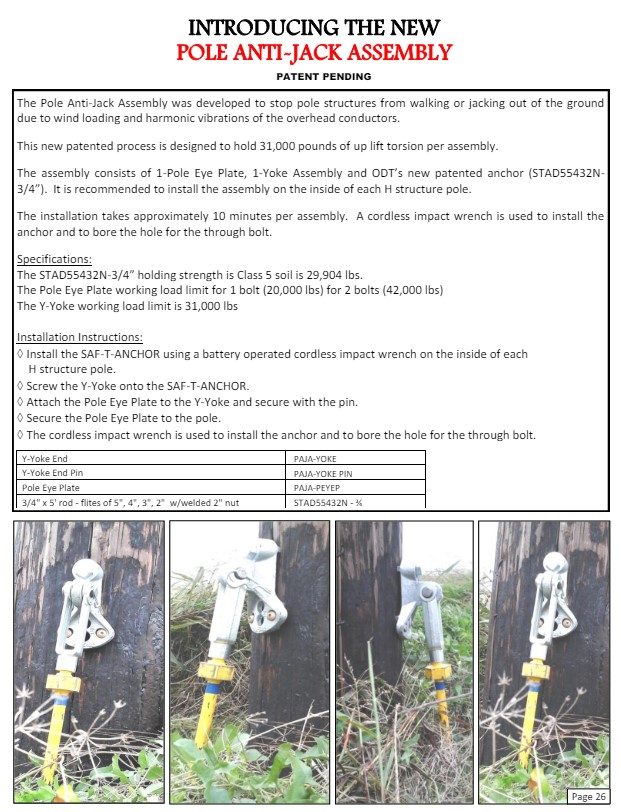

The Pole Anti-Jack Assembly was developed to stop pole structures from walking or jacking out of the ground due to wind loading and harmonic vibrations of the overhead conductors.

This new patented process is designed to hold 31,000 pounds of up lift torsion per assembly.

The assembly consists of 1-Pole Eye Plate, 1-Yoke Assembly and ODT’s new patented anchor (STAD55432N-3/4”). It is recommended to install the assembly on the inside of each H structure pole.

The installation takes approximately 10 minutes per assembly. A cordless impact wrench is used to install the anchor and to bore the hole for the through bolt.

Anchor Creep - Definition

Provided above are excerpts from articles discussing Anchor Creep

The most common problem with anchoring is soil type and “creep”. When tension is applied to newly installed anchors, the anchor will continue to creep because the soil has been disturbed. It takes an average of 10 years for soil to return to full compaction. Some soil types will not compact, such as caliche and loose sand.

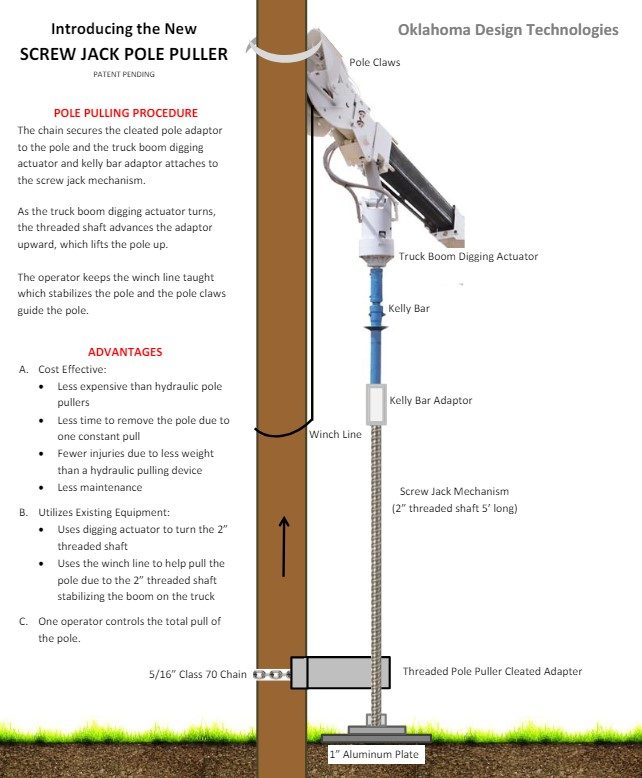

Screw Jack Pole Puller

Innovative Products provided by Oklahoma Design Technologies

This is a new product that will be available soon...Please contact ODT for availability.

©Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.